Laboratory 1 - Synthesis, Processing, Functionalization.

The mission of the laboratory is to facilitate the technological transfer of research results and laboratory technologies developed in INFLPR based on the concept of "scaling-up approach" and to provide synthesis, processing and functionalization services to potential economic partners or interested institutions.

Thin film synthesis services by PLD and Magnetron sputtering on large surfaces (up to 8 ”).

Thin film synthesis services by PLD and Magnetron sputtering on large surfaces (up to 8 ”).- Plasma processing at atmospheric pressure of various surfaces.

- Production of transparent ceramics for active laser media, various advanced materials and nanomaterials.

|

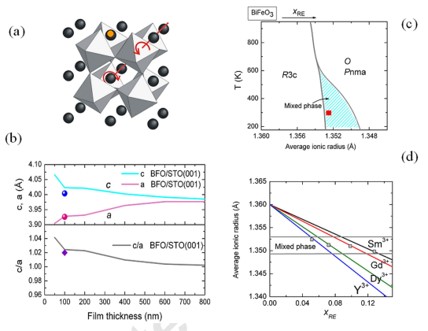

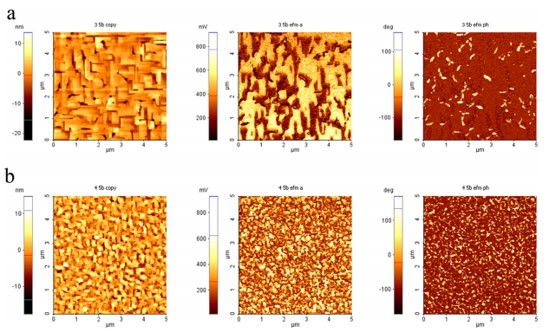

Joining Chemical Pressure and Epitaxial Strain to Yield Y-doped BiFeO3 Thin Films with High Dielectric Response N. D. Scarisoreanu et al, Scientific Reports (2016) |

Large equipment / institutional facilities:

-

Thin film deposition systems on large areas > 200 mm.

-

Robotic surface processing equipment with atmospheric pressure plasma.

-

Ultrashort pulse laser (CEP, 25 fs, 1 mJ, 1 kHZ, high contrast).

-

Cold isostatic press.

-

Hot isostatic press.

-

Oven 1800 C.

-

Oven 1800 C - oxygen.

-

Oven 3,000 ° C (vacuum, H2, inert gases)

|

Rolling dopant and strain in Y-doped BiFeO3 epitaxial thin films for photoelectrochemical water splitting F. Haydous et al, Scientific Reports (2018) |

Equipment specifications

-

Pulsed Laser Deposition system (200 mm / 8 ") SMP 800 Platform

- Excimer laser included

- Up to 4 integrated targets (minimum 3 targets)

- Up to 200 mm deposition surface

- Deposition temperature of substrate: room temperature - up to 800⁰C

responsible staff - Nicu Scarisoreanu

users - Florin Andrei

- Ultrashort pulse laser

- Carrier envelope phase stabilization

- Pulse 25 fs

- Energy 1 mJ

- Frequency 1 kHZ

- High contrast

responsible staff - Nicu Scarisoreanu

users -

- Cold isostatic press

responsible staff - Florin Andrei

users - George Stanciu

- 1800°C Furnace

responsible staff - Florin Andrei

users - George Stanciu

-

1800°C Furnace in oxygen medium

responsible staff - Florin Andrei

users - George Stanciu

-

3,000°C Furnace in vacuum, H2, inert gases

responsible staff - Florin Andrei

users - George Stanciu

-

Magnetron sputtering (200 mm / 8 ") with e-beam evaporation, dual plasma source at atmospheric pressure

- 4 magnetron guns of 3” diameter, 2 alternative guns of 2”

- 4-port e-beam source

- Up to 200 mm deposition surface

- Residual gas analyser operating at process pressures

- Thin film thickness monitoring

responsible staff - Bogdana Mitu

users - Nicu Scarisoreanu

-

Hot isostatic press

responsible staff - Florin Andrei

users - George Stanciu

-

Robotic surface processing equipment with atmospheric pressure plasma

- Jet type plasma source with atmospheric pressure operation, powered by high power and frequency generator (~ 5 kW)

- Working gases: nitrogen, air, possibility of reactive gas introduction, gas mixtures and precursor injection system

- Robotic system for deposits up to 50 cm in one direction and robotic arm for 3D material processing

- Surface treatment / deposition speed up to 20 m/min

responsible staff - Bogdana Mitu

users -

Laboratory Team

Responsible of Laboratory

Dr. Nicu Doinel Scarisoreanu - CS1

Dr. Bogdana Mitu - CS1

Drd. Florin Andrei - ACS

Research and development activity

-

Synthesis of large area coatings / thin films of advanced oxide, oxynitric and metallic materials for operation in extreme conditions (ITER, ELI, CETAL), dielectric and metallic coatings and films for CETAL and ELI facilities.

-

Synthesis of transparent ceramics

-

Large area coatings of nanocomposite materials for biological and biomedical applications

-

Production of nanomaterials and nanostructures for energy and ecotechnologies (photocatalysis, energy harvesting, photovoltaics, batteries).

-

Production of multicomponent or multilayer thin films for electronic devices and new materials applied on a large area for applications in sensors.

-

Surface treatments

National and international novelty degree: industrial standard deposition systems on 8-inch supports.